-

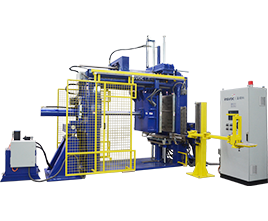

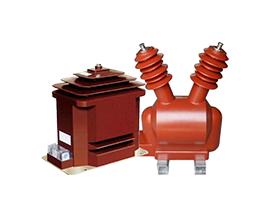

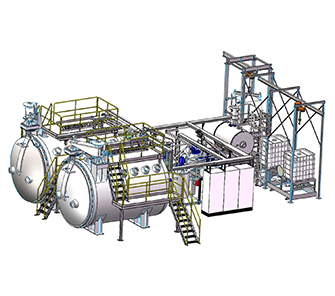

Dry-type transformer uses epoxy resin for the fasten and insulation of the coil. It needs casting, pressure impregnation under vacuum, make sure that the bubbles in the coil are completely removed, enhance the cracking resistance of the product and improve the product’s quality.

-

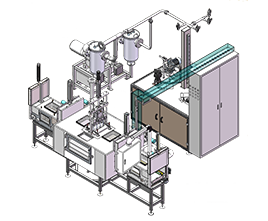

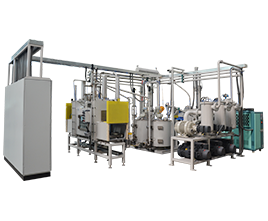

●Small package filler or dust-free ton bag, to prevent dust pollution in the workshop, the filler mixing and heating under vacuum, let the material degassing and dewatering sufficiently.

●Resin, hardener automatically continuous loading, the material will be divided into two non-reactive A/B components, material loading by ratio according to the automatic metering, loading accurate and stable.

● Single component material mixing and heating under vacuum, adopts the umbrella thin film degassing or continuous online degassing technology to the conical thin film degassing or continuous on-line degassing technology fast material moisture will quick clean off the water vapour of the material.

●A/B component is measured and conveying automatically according to the ratio, uses dynamic or static mixing mode to mix the A/B components, the mixture is delivered into the products mould in the vacuum casting tank, casting under vacuum, then pressure impregnation. -

● Environmental protection design, energy saving, reduce emission and labor intensity.

● Material automatic loading, metering, mixing, conveying and injection moulding.

● The powerful control system monitors the equipment status and process flow, records real-time the relevant parameters of the production, and the data can be read anytime.

● Servo metering pump for the material ratio metering is more accurate and stable, the use of silicon carbide ceramic piston is wear resistance and withstand voltage design, with long service life.

insvac@insvac.com