-

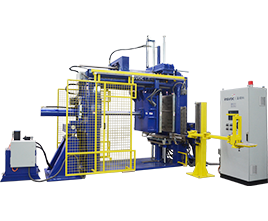

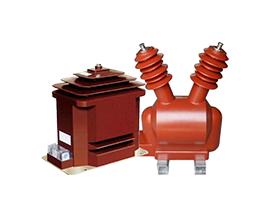

After finished the assembly of the generator stator and rotor windings, it shall be insulated under vacuum, insulating paint or epoxy resin will be applied to vacuum impregnation for the insulation of the inner and surface of the coil.

-

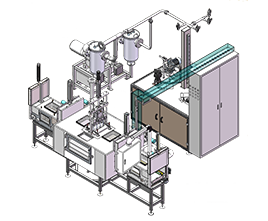

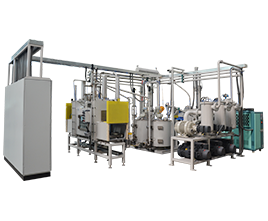

●The insulating material is stored in the storage tank, which is provided with mixing and heating functions, the material is processed under vacuum to completely remove moisture of the insulating material.

● The motor is vacuumized and degassed in the impregnation tank, which has a heating function to improve the degassing efficiency and better remove the inside moisture.

● After finished the degassing of the motor, pass the insulating material into the impregnation tank for vacuum impregnation

● After the impregnation, it can be pressurized to make the insulating material more fully impregnated, better adhered to the product and improve the insulation quality of the product. -

● The raw material is mixing, heating and degassing under vacuum, improve the insulation performance of the material

●The multi-components material is automatically formulation metering, fully mixing and automatically conveying to the dipping tank for vacuum impregnation.

● The impregnation tank with heating and pressurized design, improving the impregnation efficiency and the quality of the product.

● The control system monitors the equipment status real time, monitors the process flow of the products impregnation, records each process parameter.

insvac@insvac.com