-

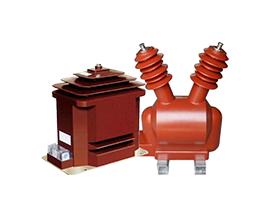

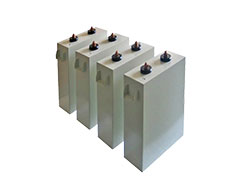

Locomotive capacitor uses epoxy resin or polyurethane as heat curing material for insulation and fixed, which have advantages of casting under vacuum with safety explosion-proof, light weight, maintenance free, anti breakdown, high insulation performance and so on. The locomotive capacitor is widely used in electric vehicles, high-speed trains, rail transportation, etc.

-

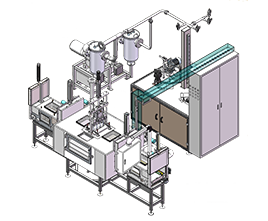

●The insulating material is heating, dewatering and degassing under vacuum, the water vapor of the raw material is completely treated.

● A/B components are measured accurately by servo metering pump, ensure the stability of material formulation.

● A/B components are mixing by the static mixer and finally casting into the product in the vacuum tank, then finish the automatically casting and impregnation. -

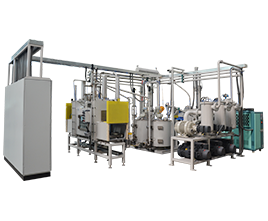

● Compatible with all kinds of sizing material, heating, dewatering and degassing under vacuum.

● Servo metering precise control the material ratio, real-time monitoring and automatic adjustment, ensure the stability of material formulation.

● Dispensing under vacuum can satisfy various dispensing modes, it can set multi-stage vacuum degree, multi-stage casting volume, multi-stage casting speed to adapt to the vacuum casting process of all kinds products.

insvac@insvac.com