-

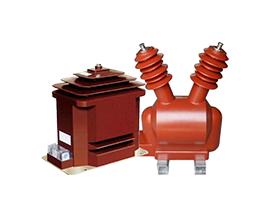

The HV box works in the situation of high temperature, high frequency, high voltage, large current, coupled with the impact of the external environment, which is wet, dust or other factors, the higher the chance of damage. Dispensing of the HV box should fully dewatering and degassing under vacuum, the material should also deal with under vacuum, in order to improve the product quality.

-

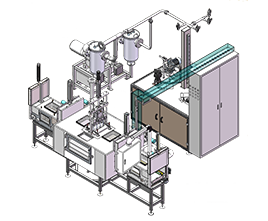

● The epoxy resin/ Flexane / Hardener are heated and umbrella thin-film degassed under vacuum in the degassing tank, or a continuous on-line degassing method is used for degassing during loading, then the charging can be used immediately

● The servo control dosing pump is adopted to ensure the accurate material formulation, mixing through the static mixer. The mixture is even with good effect, fresh material and good flowability.

● The mixture is storage in the second metering cylinder, casting accurately through second metering, setting the casting volume and speed according to the product.

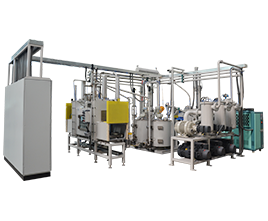

● Degassing, dispensing, impregnation under vacuum -

●Umbrella thin-film degassing or continuous on-line degassing has the advantage of high efficiency and rapid degassing

● Servo dosing pump for material formulation, more accurate and stable.

● Vacuum plasma activation cleaning can improve the adhesion of epoxy resin and the quality of products

●Formulation monitor on-line, real time monitoring the ratio accuracy

●The second dosing distribution, small casting volume and uniform, meet variable casting requirement.

●Triple-chambers vacuum casting with production line to improve production efficiency

insvac@insvac.com