-

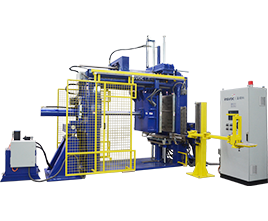

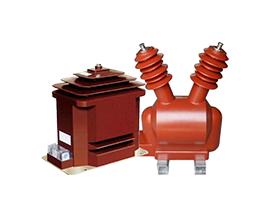

Silicone rubber is widely used as the special rubber, because of its excellent heat resistance, weather resistance and electrical insulation. Liquid silicone rubber (LsR) generally use double components packaging, has the advantages of certain fluidity and easy to transport before vulcanization, it can be used in liquid injection clamping machine for molding. The usual vulcanization methods are room temperature vulcanization and heating acceleration vulcanization. Compared with the traditional heat vulcanization molding process, with time saving and energy saving, after treatment process can be avoided, high rate of finished products, the low comprehensive cost advantages and so on.

-

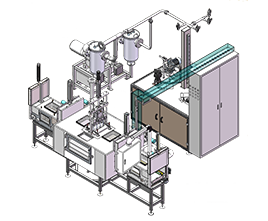

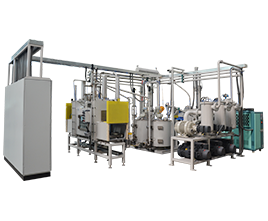

●A, B material mixing and metering according to same-size ratio, continuous uniform supplement

● Static mixer mixing uniformity

● Once molding, no waste and automatic injection -

● The metering pump adopts continuous material supplement mode design, ensure uninterrupted supplement during injection, which avoid the product curing due to the suspension of the material supplement and also avoid the layering.

● Real time on-line monitoring of conveying pressure and ratio

● Multi stage pressure control of gel shrinkage device

●The mixer adopts metal static mixing, mixing evenly, wear resistance, durability and convenient maintenance

●With double barrel bottom cylinder jacking device, used to promote the discharge at the bottom of the remaining material.

insvac@insvac.com