-

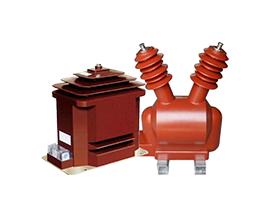

Dry-type HV sleeve uses epoxy resin and hardener as insulating materials, casting under vacuum, then pressure impregnation, and the final solidification in the casting tank, the requirements of the material degassing and mixing control are high, any one bubbles may lead to scrap of the whole product.

-

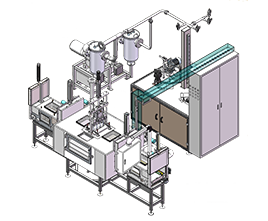

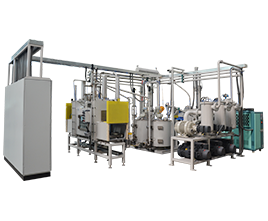

● Resin or hardener adopts the continuous loading mode, switching the material barrel automatically, low level alarm

● The resin and the hardener adopt on-line degassing method, degassing while loading, the material is loaded into the metering tank to complete degassing, and the utility model can be used immediately to ensure the uninterrupted supplement of the materials.

● Servo control metering pump for material metering, delivery the material in to static mixer according to the set formulation, after mixing then finally casting into the products.

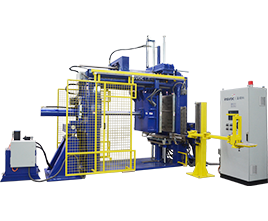

● After the product casting is finished, there is pressure impregnation, and solidified according the solidified curve in the casting tank. -

●Material automatic loading, metering, mixing, conveying and injection moulding.

●The powerful control system monitors the equipment status and process flow, records real-time the relevant parameters of the production, and the data can be read anytime.

●Servo metering pump for the material ratio metering is more accurate and stable.

●The compression design of the casting tank, realize the compression and impregnation of the products, it uses the oil heating to control the multi section temperature zone, the temperature is uniform, finishing the whole curing process according to the set temperature control.

insvac@insvac.com