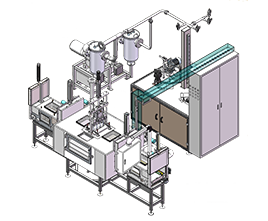

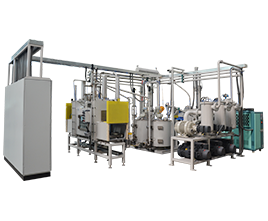

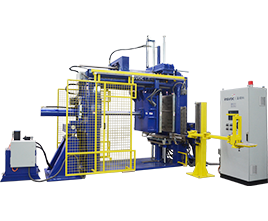

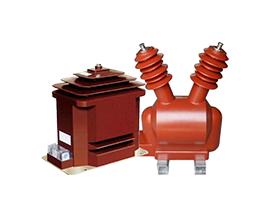

vDMC series Dynamic Mixing Vacuum Casting Equipment is suitable for the vacuum casting process of medium/low voltage insulators, CT/PT and so on. The system adopts classical dynamic mixing formulation, it can be customized according to the customer’s requirement, on the basis of the material, process, capacity, operation requirement and characteristics of the casting product.

vDMC series Dynamic Mixing Vacuum Casting Equipment controls automatically the process of loading, formulation, degassing, mixing, vacuum and heating. Real time acquisition, monitoring, display and storage the production parameters such as weight, temperature, vacuum and so on. The process variable data can be freely modified according to the process requirements, the equipment can be remotely monitored, to assist the customers in the diagnosis and removal of equipment breakdown.

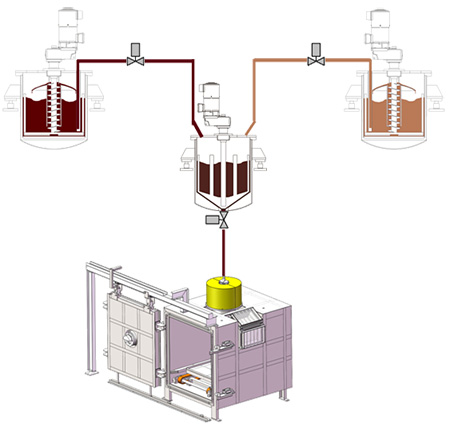

Process Flow ● Material loading ● A/B formulation ● Degassing & Impregnation ● Vacuum Storage ● Metering & Transportation ● Dynamic mixing ● Vacuum casting | Process Control ● Electric control ● Weighing system ● Metering system ● Vacuum system ● Heating system ● Cooling system ● Cleaning system | Characteristic ● Dust-proof ● Supply material and product continually ● Degas efficiently and energy saving ● Precise formulation ● Dynamic mixing thoroughly ● Casting automatically and vacuum impregnation ● Formulate process parameters ● Intelligent control | Options ● Connect to MES system |

vDMC series Dynamic Mixing Vacuum Casting Equipment is suitable for the vacuum casting process of medium/low voltage insulators, CT/PT and so on.