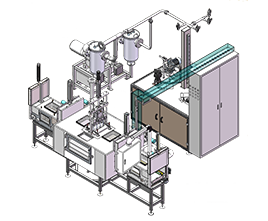

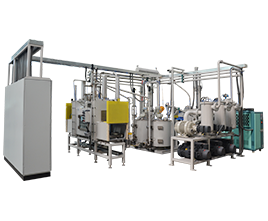

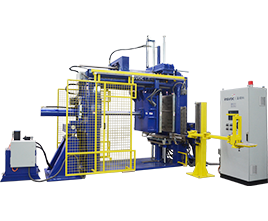

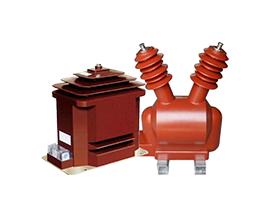

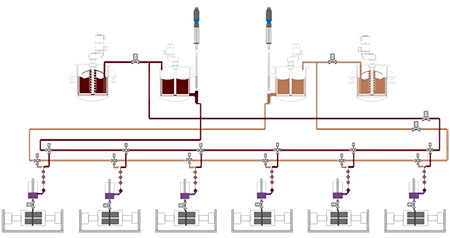

vAPG Series Static Mixing & Casting System is exclusively used in the automatic pressure gelation (APG) production of the medium/high voltage insulators, such as insulation, embedded pole, contact box, wall bushing and so on. This kind of system centralized controls the whole process such as materials filling, formulation, mixing, pressure injection and shrinkage compensation. It has advantages in high automation, high productivity and quality.

vAPG Series Static Mixing & Casting System adopts servo driven which is controlled by servo axis control system. Metal static mixing, direct casting the material into the mould of the clamping machine or transfer to the injector, which according to the, can realize multi speed, multi-stage injection pressure, and then automatic pressure gel by the shrinkage device, automatic injection and molding. The material formulation process management, can storage and call the data arbitrarily.

Process Flow ● Material loading ● A/B formulation ● Degassing & Impregnation ● Vacuum storage ● Metering & Transportation ● Static mixing ● Vacuum casting ● Automatic pressure shrinkage

| Process Control ● Electric control ● Weighing system ● Metering system ● Vacuum system ● Heating system ● Cooling system ● Cleaning system

| Characteristic ● Dust-proof ● Supply material and product continually ● Degas efficiently and energy saving ● Precise formulation ● Fresh casting compound ● Casting automatically and pressure gelation ● Formulate process parameters ● Intelligent control

| Options ● Mobile cleaning device ● Connect to MES system

|

vAPG Series Static Mixing & Casting System is exclusively used in the automatic pressure gelation (APG) production of the medium/high voltage insulators, such as insulation, embedded pole, contact box, wall bushing and so on.