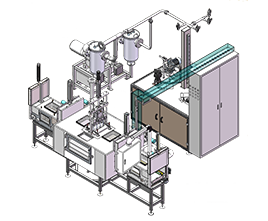

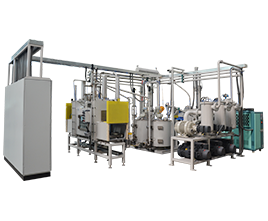

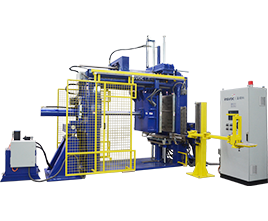

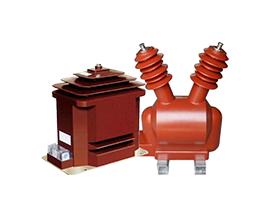

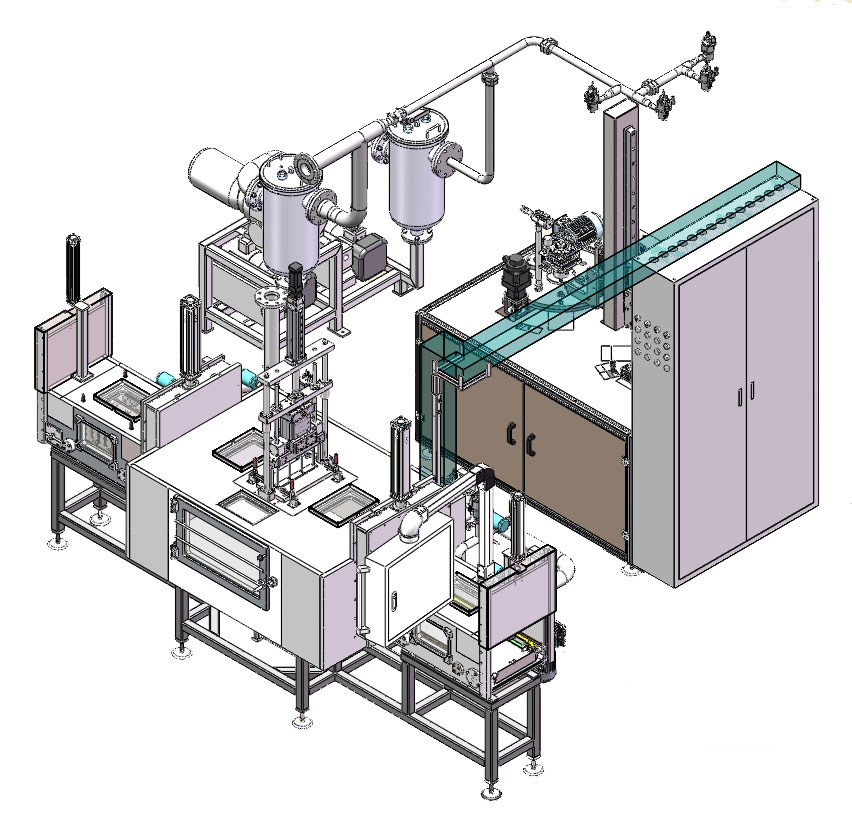

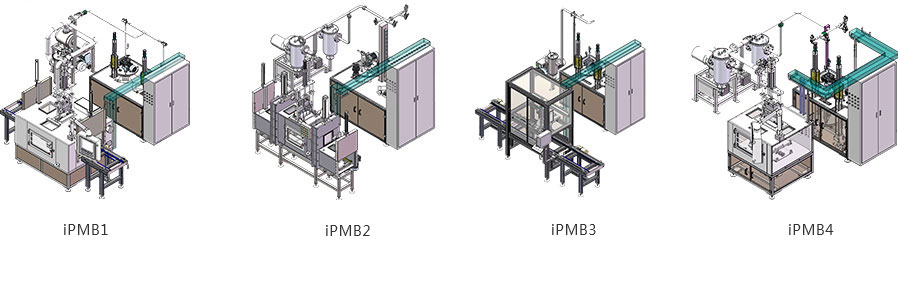

iPMB Series Vacuum Dispensing Machine is used in the casting process of LCD panel, circuit boards, automotive electronics, capacitors, transformers, high voltage box, ignition coil, motor, sensor, small motor, inverter, other low/medium/high voltage insulation and so on. Formulation manage control the production process, such as loading, formulation, metering, mixing, casting and others, realize the automation of production, improve the production efficiency and the product qualification rate.

(1)-3dc70492-d23a-4ace-afdb-ecf7f72bf826.png)

Standard ● Vacuum loading device ● Degassing storage unit ● Gear pump loading system ● Precision metering system ● Static mixing system ● Vacuum dispensing system ● Heating system ● Vacuum system ● Control system

| Options ● Loading system ---18L/200L Charging station ---100L/150L Pour tank ---18L/200L Glue pump ---Pneumatic, electric suction pump ● Degassing & formulation ---Two stage tank formulation and degassing ---Static/Dynamic degassing online ● Anti settling self circulation device ● Connect to ERP/MES system

| Extensions ● Product automatic assembly line ● Tray circulate system ● Blanking system ● Product liquid position detection ● Multi axis dispensing system ● CCD visual identity system ● Multi axis robot arm system ● Tunnel oven/Stereo oven ● Plasma cleaning system ● Precision glue filling system

| Characteristic ● Reasonable layout and compact structure ● Reasonable design and strong expansibility ● Continuous supplement, continuous production ● Thin film degassing and energy efficient ● Servo mitering, stable formulation ● Static mixing ● Fresh compound ● Intelligent control, automation production ● Formulation manage the production process ● Easy operation and maintenance

|

iPMB Series Vacuum Dispensing Machine is used in the casting process of LCD panel, circuit boards, automotive electronics, capacitors, transformers, high voltage box, ignition coil, motor, sensor, small motor, inverter and other low/medium/high voltage insulations, etc.