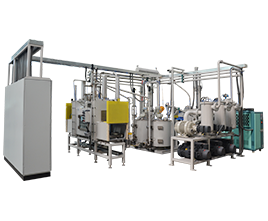

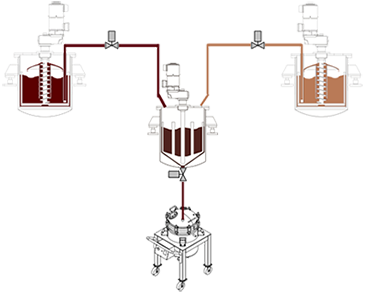

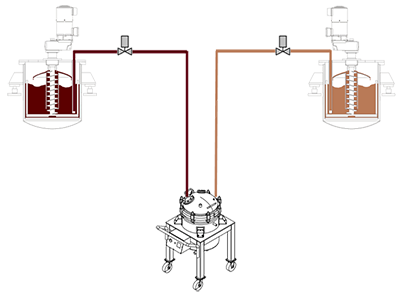

vDFC Series Vacuum Formulation & Mixing System can be designed according to the customer’s requirement, contains large formulation center of single component and multi components, which is suitable for materials with different formula and colors. This kind of system is used in materials formulation of APG production, with big capacity, flexible formulation and mixing even. It can fresh compound according to the production requirement.

vDFC Series Vacuum Formulation & Mixing System controls automatically the process of loading, formulation, degassing, mixing, vacuum and heating. Real time acquisition, monitoring, display and storage the production parameters such as weight, temperature, vacuum and so on. The system sets permissions management, the operator can change the basic parameters of the device, the administrator can modify the equipment process parameters. The equipment can be remotely monitored, to assist the customers in the diagnosis and removal of equipment breakdown.

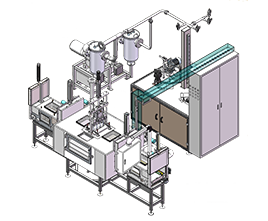

Process Flow ● Material loading ● A/B formulation ● Degassing & Impregnation ● Vacuum Storage ● Metering & Transportation ● Dynamic mixing

| Process Control ● Electric control ● Weighing system ● Metering system ● Vacuum system ● Heating & Cooling system ● Cleaning system

| Characteristic ● Dust-proof ● Supply material and product continually ● Degas efficiently and energy saving ● Precise formulation ● Dynamic mixing thoroughly ● Formulate process parameters ● Intelligent control

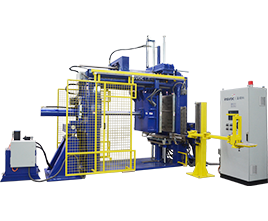

| Options ● Connect to MES system ● Automatic pressure shrinkage device |

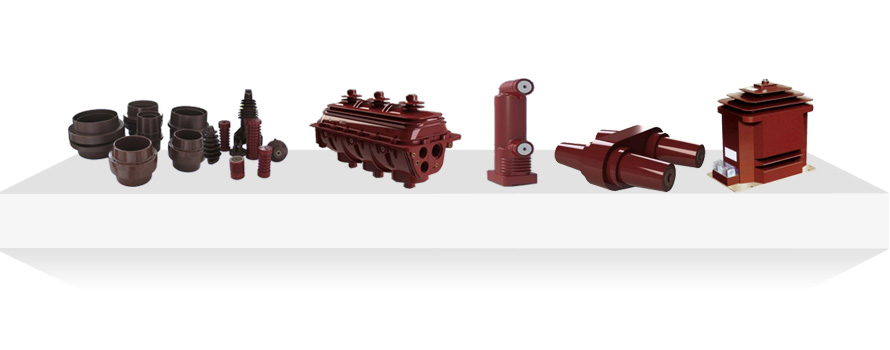

vDFC series Vacuum Formulation & Mixing System is used in the vacuum formulation and mixing of the medium/high voltage insulators, such as insulation, embedded pole, contact box, bull washing and so on.