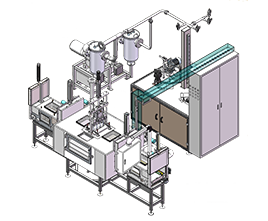

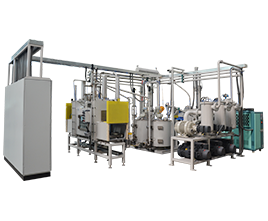

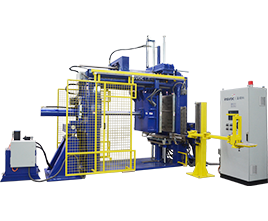

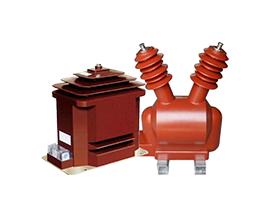

cFCM Series clamping machines are widely used in automatic pressure gelation process for high/medium voltage insulators or silicon rubber products. For example, APG or VPG production of post insulators, embedded poles, contact box, wall bushing, CT/PT, silicon rubber bushing and so on.

cFCM Series Frame Clamping Machines adopts hydraulic proportional control , automatic casting, setting arbitrary the rotation tilt with vertical/horizontal 0-7°, achieve rotation during injection, the action can be managed into the program. The machine can select several speed and pressure to finish casting and molding automatic. Multi program operation management can storage and call the data arbitrary.

Standard ● Main frame ● Dynamic & Static mold device ● Top core ● Top horizontal moving device ● Bottom core ● Bottom horizontal moving device ● Control system ● Hydraulic system ● Heating system | Option ● Side core ● Side injector ● Rotation tilt ● Safety guard ● Synchronization demould ● Automatic pressure shrinkage device ● Robot transfer ● Quick mold change system ● Connect to MES/ERP system | Characteristic ● Welding frame with fully tempering, ensure high rigidity and stability ● Precise finish machining ● Bottom core is durable ● Funnel collector to protect bottom core ● Tilting can be controlled automatically ● Programmed management |

cFCM Series Frame Clamping Machine is widely used in the production process of post insulator, embedded pole, contact box, wall bushing, CT/PT, silicone rubber sleeve and so on.