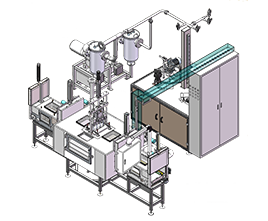

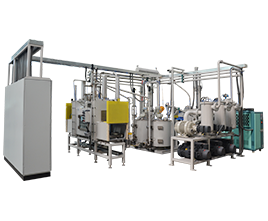

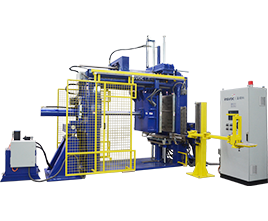

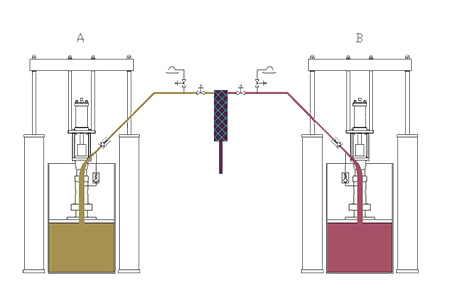

cDD series Double-components Injection Equipment is exclusively used in the casting and molding of hydraulic silicone or new type epoxy resin (Casting & go), with the functions of compression, metering, mixing, casting and so on. Formula manages the casting process and real-time record the parameters like filling pressure, capacity, temperature etc, then generate report automatically.

Metering system adopts servo proportional hydraulic system, accurately control the system pressure, casting flow and casting pressure. Through the detention of servo proportional valve and shifting, can adjust the casting volume and speed real-time, make sure the formulation accuracy. Metering pump is designed with the mode of continuous supplement, supplies the material continually during the casting.

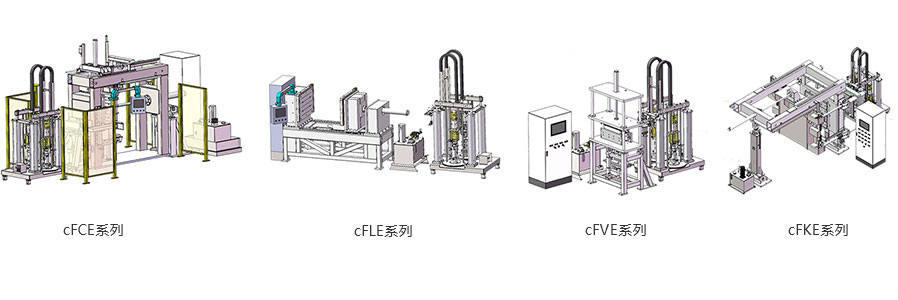

Process Flow ● Material loading ● Quick degassing ● Servo metering ● Static mixing ● Casting & Molding | Process Control ● Control system ● Servo metering system ● Heating system | Characteristic ● Static mixing technology, mixing thoroughly ● High pressure is suitable for high viscosity materials ● Formulation test online ● Gelation compensation device ● The pressure plate design to degassing efficiently ● None-material warning ● Heating system is optional ● Servo hydraulic system reduce noisy and energy-saving ● Connect to MES system, data management | Metering Control Options ● Servo motor axis control ● Servo hydraulic axis control ● Proportion of synchronous in series

|

cDD series Double-components Injection Equipment is exclusively used in the casting and molding of hydraulic silicone or new type epoxy resin (Casting & go).